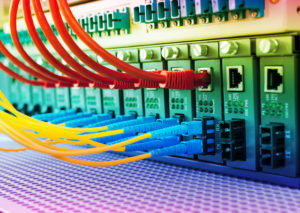

Traditional coaxial or copper cables will be replaced with quicker and more reliable fiber networks.

It is predicted that the spread of 5G connectivity onto a global scale will happen at some point within the next five years, as they increasingly connected world will begin to demand the increased bandwidth provided by the network connectivity. As this shift happens, traditional coaxial or copper cables will be replaced with quicker and more reliable fiber networks. Network providers should prepare to install newer fiber systems and upgrade and maintain any existing fiber infrastructures. To maintain a secure fiber network, service providers have to implement a proper fiber-cleaning procedure to ensure network performance and reliability for smartphones and computers. Here’s why fiber cleanliness is so essential for 5G.

Why Cleaning Your Fiber Infrastructure is Important

Ensuring that all connections and splices within your fiber network are squeaky clean is crucial for avoiding several issues, including:

- Back reflection, or when a signal suddenly is diverted back to its original source.

- A complete system shutdown.

- Insertion loss, or weakened signal.

5G connectivity can’t be sustained on a network that’s prone to any of those issues, because every bit of power is required for optimum performance.

Clean Newer Fiber Cables

Patch cords and jumpers, even if bought directly from the factory, don’t guarantee cleanliness. End caps are usually not cleaned before packaging, so dust and any other leftover debris might be trapped inside. There are several ways that cables can experience wear while traveling from the factory to installation, so installers must be thoroughly clean. Make sure both ends of the connector pair right before they’re mated are cleaned to ensure clean fiber connections and an eventual secure network.

Pick the Right Cleaning Fluid

Fiber industry organizations usually recommend “wet/dry” cleaning as the best method for cleaning fiber end-faces. Water and isopropyl alcohol are popular choices, but they’re difficult to keep uncontaminated. The best option for ensuring a 5G connection is to clean the end-faces with engineered optical-grade cleaning fluids for fiber-optic connectors. These fluids are static-dissipative, fast-drying, and sold in sealed packaging. This is one way to ensure you have a quick 5G connection for browsing and security against cybercrime.

Don’t Forget to Inspect

Fiber-optic contamination is minuscule, so it can only be seen with a microscope. The ideal method for catching contamination is by using the “inspect, clean, and inspect” process. Insert a piece for contamination, clean off the end-faces, and then inspect again to ensure any debris is gone.

En-Net Services Can Help Today

Experience a superior method of getting the public sector technology solutions you need through forming a partnership with En-Net Services. Our seasoned team members are familiar with the distinct purchasing and procurement cycles of state and local governments, as well as Federal, K-12 education, and higher education entities. En-Net is a certified Maryland Small Business Reserve with contract vehicles and sub-contracting partnerships to meet all contracting requirements.

To find out more about our hardware services, printing, and imaging services, or to hear more about how a dynamic team can help meet your information technology needs, send us an email or give us a call at (301)-846-9901 today!